Xiamen Yulong Machinery Co., Ltd. launched the "4M" manufacturing process to implement the project

- Categories:Company news

- Author:

- Origin:

- Time of issue:2021-02-20

- Views:0

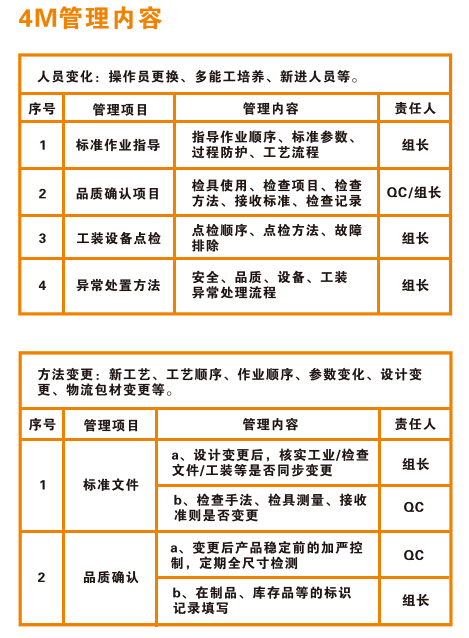

(Summary description)The core of manufacturing process management is 4M, namely: personnel management, equipment management, material management, and method management. A stable and controlled manufacturing process will not be abnormal. If there is an abnormality, then a certain element of the 4M manufacturing process must have changed. Therefore, in order to continuously and effectively maintain high-efficiency production and product quality stability, it is necessary to effectively monitor 4M changes.

Under the attention and promotion of the leaders of Yulong Industry and Xiamen Yulong Company, Xiamen Yulong officially launched on March 23, 2015: "4M" to implement special improvement activities. The activity was initially conducted in the machine cutting group and the stamping group, and after 2-3 months of operation, it was promoted in Xiamen Yulong's entire plant. The activity is led by the manufacturing department, with the participation of the technology department, tooling department, quality control department, and business department. Through daily 4M monitoring of the manufacturing process, the unstable factors in the production process can be discovered and resolved in time to ensure process control.

The implementation of 4M management activities is aimed at improving product quality, thereby improving production efficiency, and on this basis, improving the quality awareness of all employees and the awareness of standardized operations, and changing passive quality management to active quality management is an important connotation of realizing total quality management. , Is also the key to quality assurance.

Xiamen Yulong Machinery Co., Ltd. launched the "4M" manufacturing process to implement the project

(Summary description)The core of manufacturing process management is 4M, namely: personnel management, equipment management, material management, and method management. A stable and controlled manufacturing process will not be abnormal. If there is an abnormality, then a certain element of the 4M manufacturing process must have changed. Therefore, in order to continuously and effectively maintain high-efficiency production and product quality stability, it is necessary to effectively monitor 4M changes.

Under the attention and promotion of the leaders of Yulong Industry and Xiamen Yulong Company, Xiamen Yulong officially launched on March 23, 2015: "4M" to implement special improvement activities. The activity was initially conducted in the machine cutting group and the stamping group, and after 2-3 months of operation, it was promoted in Xiamen Yulong's entire plant. The activity is led by the manufacturing department, with the participation of the technology department, tooling department, quality control department, and business department. Through daily 4M monitoring of the manufacturing process, the unstable factors in the production process can be discovered and resolved in time to ensure process control.

The implementation of 4M management activities is aimed at improving product quality, thereby improving production efficiency, and on this basis, improving the quality awareness of all employees and the awareness of standardized operations, and changing passive quality management to active quality management is an important connotation of realizing total quality management. , Is also the key to quality assurance.

- Categories:Company news

- Author:

- Origin:

- Time of issue:2021-02-20

- Views:0

The core of manufacturing process management is 4M, namely: personnel management, equipment management, material management, and method management. A stable and controlled manufacturing process will not be abnormal. If there is an abnormality, then a certain element of the 4M manufacturing process must have changed. Therefore, in order to continuously and effectively maintain high-efficiency production and product quality stability, it is necessary to effectively monitor 4M changes.

Under the attention and promotion of the leaders of Yulong Industry and Xiamen Yulong Company, Xiamen Yulong officially launched on March 23, 2015: "4M" to implement special improvement activities. The activity was initially conducted in the machine cutting group and the stamping group, and after 2-3 months of operation, it was promoted in Xiamen Yulong's entire plant. The activity is led by the manufacturing department, with the participation of the technology department, tooling department, quality control department, and business department. Through daily 4M monitoring of the manufacturing process, the unstable factors in the production process can be discovered and resolved in time to ensure process control.

The implementation of 4M management activities is aimed at improving product quality, thereby improving production efficiency, and on this basis, improving the quality awareness of all employees and the awareness of standardized operations, and changing passive quality management to active quality management is an important connotation of realizing total quality management. , Is also the key to quality assurance.

Scan the QR code to read on your phone

CONTACT INFORMATION

Add:No. 66, Qingxi Road, Guankou Industrial Zone, Jimei District, Xiamen

Postcode:361023

Tel:0592-6360508

Fax:0592-5776612

URL:http://www.xmyulong.com

E-Mail:xm-business@xmyulong.com

Add:No. 3, Lingbei 1st Road, Shiziling Industrial Park, National High-tech Zone, Haikou City, Hainan Province

Postcode:570226

Tel:0898-65520080

Fax:0898-68967881

URL:http://www.xmyulong.com

E-mail:hn-business@xmyulong.com

Add:No. 10, Dong12 Road, Xingsha Economic and Technological Development Zone, Changsha City, Hunan Province

Postcode:410137

Tel:0731-84082323

Fax:0731-85284851

URL:http://www.xmyulong.com

E-Mail:hnx-business@xmyulong.com

Add:No. 11, Jinhe 3rd Road, Shilou Town, Panyu District, Guangzhou

Postcode:511447

Tel:020-31132800

Fax:020-34869855

URL:http://www.xmyulong.com

E-Mail:gz-business@xmyulong.com

ONLINE MESSAGE

Page Copyright © 2020 Xiamen Yulong Machinery Co., Ltd. All 闽ICP备09031015号-1 OA system

中文

中文

+86 20 8489 6096

+86 20 8489 6096

Contact

Contact